Knowing the type of loads that we must power is vital to correctly determine the power rating of a Generator Set, whether it is powered by a Diesel- or Petrol-Engine or PV Modules.

The power that a Generator Set manages is not an absolute and static value. Its level tends to fluctuate according to certain factors and processes, and it does so differently in each type of unit.

For this reason, calculating the power a Generator Set needs to produce is not a simple operation. Different variables must be considered which, if not considered, can cause serious issues in your installation.

For instance, an overload in any of the phases can cause overheating and voltage imbalances. This can cause damage both in the Generator Set and the Equipment connected to it.

Start-Up

The Generator Set is going to be limited during its start-up by what is called the first step load, that is: the total transient load that the Generator Set is initially capable of enduring until reaching its stable regime with some Transient Variations in Voltage and Frequency. This is far more important for Diesel- or Petrol-Powered Generator Sets.

This is why it is important to verify the characteristics in the nameplates of the equipment connected to the Diesel- or Petrol-Powered Generator Sets, and to be aware of the possible transient effects which they may suffer during its start-up processes.

Certain equipment such as pumps or motors with variable drives, for instance, may increase their current temporarily during commissioning.

Likewise, elements such as UPS’s (Uninterruptable Power Supplies) can cause harmonic distortions which must be contemplated in our calculations.

Which Parameters Affect the Dimensioning of Loads

- The first parameter to contemplate is the type of load. As we’ve pointed out, some units experience transient increases in current during start-up. With this in mind, we will pay special attention to the following loads:

- Uninterruptable power supplies (UPS). The alternator’s rated power is oversized depending on the installation.

- Big motor loads. They can increase starting power to up to 6 times the power, depending on the type of start-up.

- Lighting loads (with special attention to sodium vapour lighting and metal halides).

- Systems with Variable Frequency Drives (VFD). These can cause an oversizing from 40 to 100%.

- Other loads which are especially sensitive to transients and voltage and frequency variations.

- Another factor we must keep in mind is the type of start-up of the motor in question. This is because of each type of starter requires a specific starting current, which must be higher than the unit’s rated current. Thus, we find that:

- The starting current of electric motors with star-delta starting will be equal to three times the rated or operating current.

- Direct starting motors: demand 6 times nominal current.

- Special attention must be paid to the technical sheet and particularly the starting current of motors with variable frequency drives as the ramp and increase in speed is configurable.

Other Important Aspects to Consider

To finish carrying out this entire calculation of power with maximum precision, other variables must be kept in mind such as:

- Power factor during start-up.

- Starter power.

- Rated power factor.

- Rated power.

- Number of start-ups.

Ultimately, one must be extremely rigorous in these calculations. To avoid any surprises, it is vital to know the type of load one is dealing with as well as its behaviour.

Usually, the objective is to Balance the Size of the Generator Set to the Load knowing what can be expected at almost every eventuality. Without proper data, this is almost impossible.

Electric Power Quality

Electric power quality is the degree to which the voltage, frequency, and waveform of a power supply system conform to established specifications. Good power quality can be defined as a steady supply voltage that stays within the prescribed range, steady AC frequency close to the rated value, and smooth voltage curve waveform (which resembles a sine wave). In general, it is useful to consider power quality as the compatibility between what comes out of an electric outlet and the load that is plugged into it. The term is used to describe electric power that drives an electrical load and the load’s ability to function properly. Without the proper power, an electrical device (or load) may malfunction, fail prematurely or not operate at all. There are many ways in which electric power can be of poor quality, and many more causes of such poor-quality power.

While “power quality” is a convenient term for many, it is the quality of the voltage – rather than power or electric current – that is described by the term.

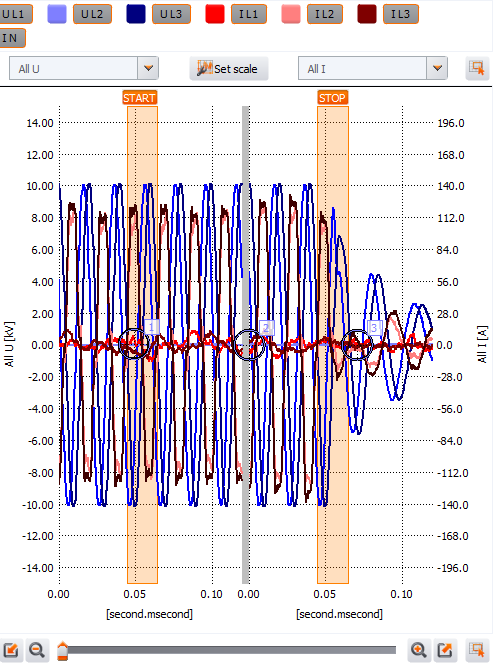

Comprehensive Monitoring

Blackouts

Blackouts are when the power for an entire area or region is unexpectedly interrupted due to a variety of reasons. Because of several “natural causes”, such as, lightning strikes on or near the power lines, high winds causing the conductors to clash into each other or breaking of conductors which then falls to the ground, sudden excessive surge in demand or the unexpected break down in power generation blackouts could occur. “Unnatural causes” such as accidental damage of power generation, transmission, distribution or reticulation equipment or sabotage of the same can also lead to blackouts.

It is not so much the blackouts that is important where it comes to Power Quality Monitoring. It is what happens immediately after the power is restored. Voltages sags and spikes and harmonic disturbances could all cause undetected long-lasting damage to the plant. These issues are unique and associated with a particular

Power Frequency Variations

This a deviation from the nominal supply frequency. The supply frequency is a function of the rotational speed of the generators used to produce the electrical energy. At any instant, the frequency depends on the balance between the load and the capacity of the available generation.

A power frequency variation occurs if a generator becomes un-synchronous with the power system, causing an inconsistency that is manifested in the form of a variation. The specified frequency variation should be always within the limits +- 2.5% Hz for grid network.

Most if not all industrial or commercial plants do not have any means of synchronising the Generator Set with the grid before or after notified power interruptions. As a result, the power to the plant is switched off momentarily for the changeover which causes numerous other undetected long-lasting damages to the plant (also see blackouts). Together with a high-quality governor synchroscope the following are the essentials conditions for synchronization can be met:

- The magnitude of the incoming voltage becomes equal.

- The machines are in phase with each other.

- The frequency of the machines remains the same.

For the parallel operation of the three-phase machines, it is essential that they are in phase with each other. The phase sequence of the device is correct at the time of the installation.

Power Transients

Transients are caused by faults in a power system that creates changes in the system quantities. These transients would cause be changes in the system conditions such as over current, under- or over-voltage, power factor, frequency and impedance variations which may result in the generation of heat in specific plant types. This is usually hard to detect because transients do not occur on a “regular basis”.

Harmonics

Electric power generators are a common source of harmonic distortion in both transmission lines and systems that use electrical equipment. Understanding how it affects your system’s performance can help you ensure its reliability.

Harmonically distorted currents stress components by causing over-voltages or over-currents, reducing component life expectancy or component failure.

Therefore, controlling or mitigating total harmonic distortion has been a significant challenge in power engineering. This is primarily due to new high-power devices such as variable speed drives that drive electrical generators.

Some of the common causes and effects of harmonics in electrical power systems are:

- Flickering lights are a common symptom of a power quality issue. A potential source of flickering lights is machinery with rapid fluctuations in load current or voltage. These machines include large motors when they are starting up, machinery with cyclo-converters such as rolling mill drives and mine winders, as well as machines that use static frequency converters such as AC motors and electric arc furnaces.

- Overheated transformers and tripped breakers could be a sign of harmonic issues, which occur when non-linear loads that draw current in abrupt pulses, rather than in a smooth sinusoidal manner, cause harmonic currents to flow back into other parts of the power system.

Over Voltage

Over-voltages which are increased voltage levels beyond the normal range can occur in almost any circuit. This can have various causes and significantly impact the system’s equipment, reliability, and performance.

This is often caused by the switching operations on unloaded lines, the “sudden” disconnection of long power line carrying a substantial load, insulation failures, ground arching or resonance at or very close to unity power factor.

Power Sags

Power sags are typically caused when high-powered electrical devices are started up. These devices include air conditioners, HVAC units, electric heaters, and factory machinery.

Power Surges

Surges result from presence of high-powered electrical motors, such as air conditioners, and household appliances in the vicinity. When such equipment is switched off, the extra voltage is dissipated through the power system.

Consulting Service

Load Profiling is a specialist service, requiring sophisticated instrumentation. Agulhas offer this as a service. Click here to order this service.