When switchgear is poorly maintained and operated continuously, it is only a matter of time before something significant occurs. However, if these extreme events go unnoticed, the consequences can be long-lasting.

During load-shedding, circuit-breakers should be opened when load-shedding starts and closed when load-shedding ends. Unfortunately, the contacts of these circuit-breakers are often concealed. As a result, if one contact fails to connect during the closing process, it may go undetected unless a thorough analysis is conducted, which is unlikely.

Negative Sequence Currents

When one phase is “missing” in a power system, it becomes unbalanced, resulting in negative sequence currents. These negative sequence currents can have detrimental effects on power system equipment and operation. Here are some potential consequences:

- Increased Heating: The absence of a phase can cause increased heating in motors, generators, and transformers. This elevated temperature can lead to potential damage or reduce the lifespan of these components.

- Mechanical Stresses: Rotating machinery, such as motors and generators, experiences mechanical stresses due to the unbalanced currents. Vibrations and torque pulsations may occur, affecting the overall system stability.

- Voltage Dips and Unbalanced Voltages: Negative sequence currents can lead to voltage dips and unbalanced voltages. These fluctuations can impact the performance of connected loads and sensitive equipment.

- Increased Power Losses: The unbalanced system results in increased power losses due to the uneven distribution of currents. This inefficiency affects overall system efficiency.

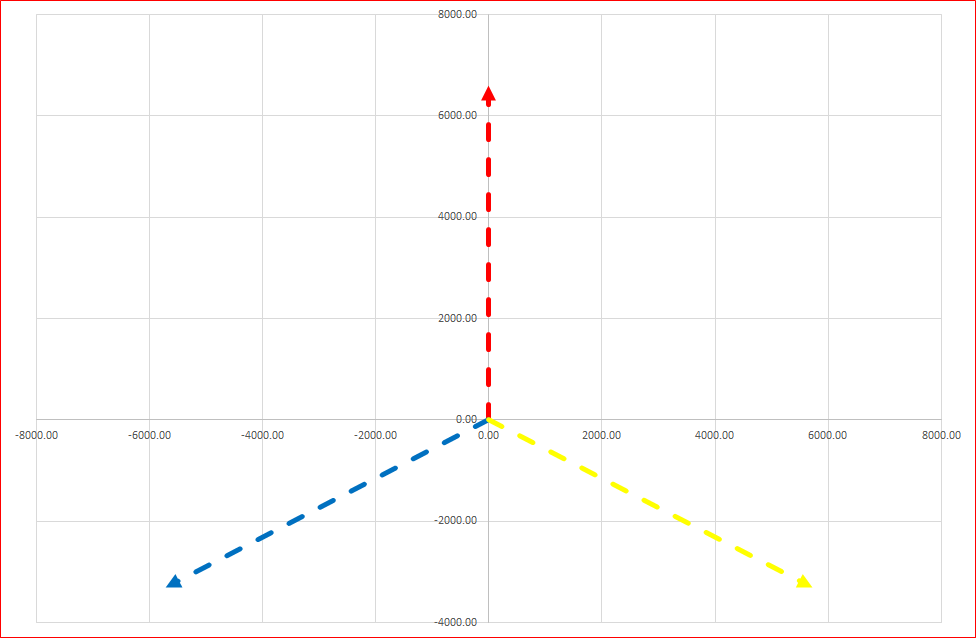

The Ideal Voltage Vector is depicted in the image with a Power Factor of 0.9 and at the rated circuit voltage of 6.6 kV. This vector represents the ideal voltage magnitude and phase angle for a balanced system, assuming a lagging power factor (cosine of the angle). It’s an essential concept in power engineering and helps analyze system behavior under different conditions.

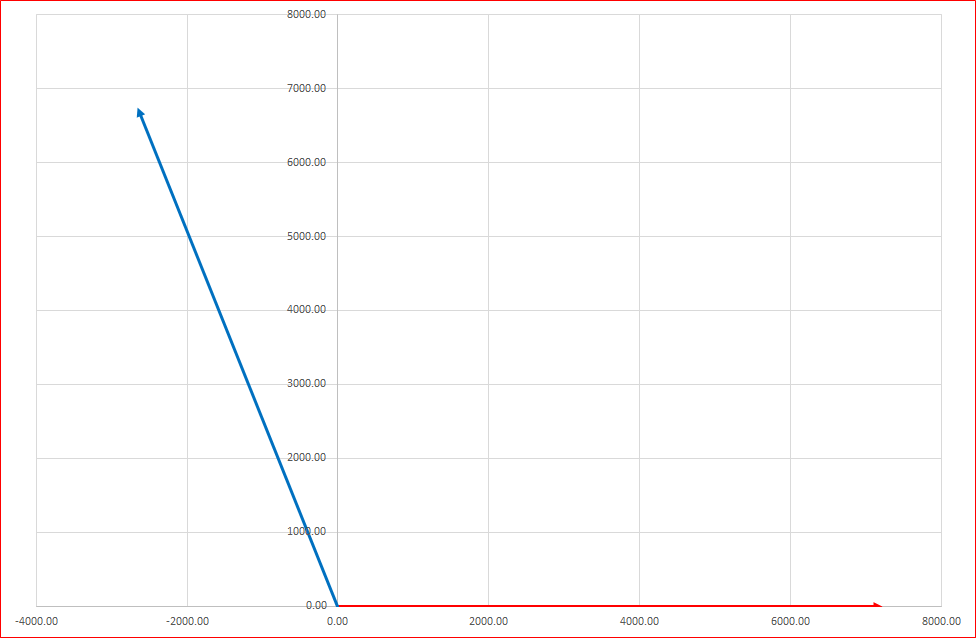

However, the Voltage Vector obtained at 03:40:00 on 2023-09-05 was totally different as can be seen in the picture below.

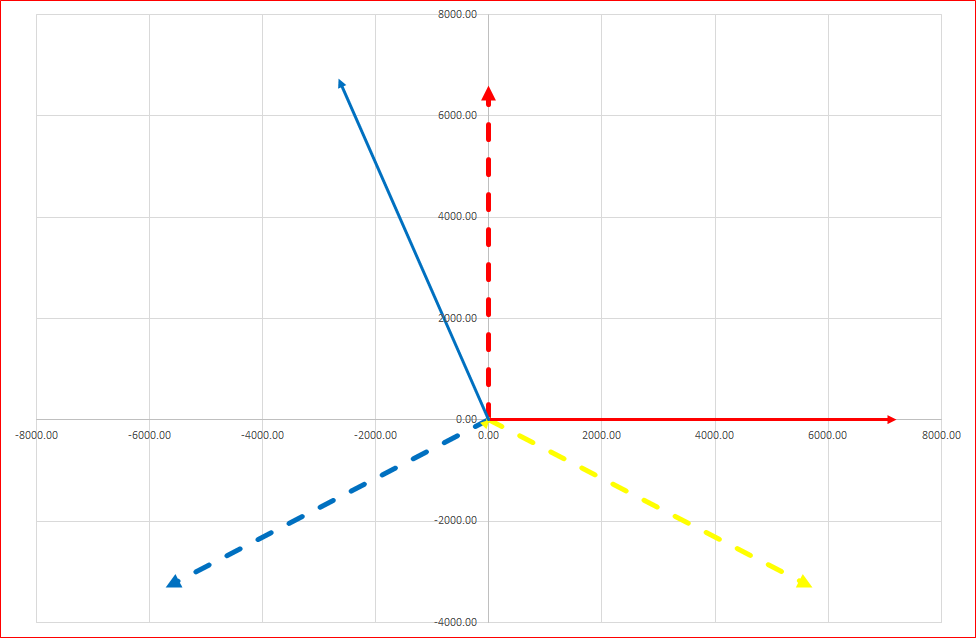

The picture below shows the Ideal Voltage Vector with the recorded Voltage Vector superimposed on top.

- Phase 1 & 3 Voltages:

- The voltages recorded on Phases 1 and 3 were over 7.2 kV.

- This means that the voltage levels for these phases exceeded 7,200 volts.

- Phase 2 Voltage:

- In contrast, the recorded voltage on Phase 2 was almost negligible.

- Negligible voltage implies that it was significantly lower than the voltages observed in Phases 1 and 3.

- Currents and System Balance:

- The currents recorded will provide additional insight.

- The unbalanced system is evident from the significant difference in voltages between the phases.

In summary, the voltage readings indicate an unbalanced system, with Phases 1 and 3 having high voltages while Phase 2 remains at a much lower level.

Consequences

- Voltage Vector:

- The voltage vector represents the voltages across the three phases (Phase 1, Phase 2, and Phase 3) in an electrical system.

- When we visualize this vector, we can imagine it as an ellipse due to the varying magnitudes and phase angles of the voltages.

- Off-Center Ellipse:

- In this case, the ellipse is described as off-center.

- This means that the voltages in the three phases are not balanced or symmetrical.

- An off-center ellipse indicates that the system is experiencing unbalanced voltages.

- Impact on Electric Motors:

- When electric motors are connected to such an unbalanced network, several issues arise:

- Bearing Stress: The off-center ellipse causes uneven magnetic forces within the motor windings. As a result, the bearings experience **uneven stress** due to the varying magnetic fields.

- Vibration: The uneven magnetic forces lead to vibration in the motor. This vibration can be significant and detrimental to the motor’s performance and longevity.

In summary, the off-center voltage ellipse can wreak havoc on electric motor bearings, causing vibration and potential damage. Engineers and maintenance personnel should address this unbalanced system to ensure optimal motor operation and prevent premature wear and tear.

Negative Phase Sequencing

- Negative phase sequencing refers to the incorrect order of phases in a three-phase electrical system.

- Detecting this issue is crucial because it affects the overall health and stability of the system.

- Why It Matters:

- While operators and maintenance crews may not always notice negative phase sequencing, it can lead to serious consequences.

- Negative sequence currents can cause motor overheating, increased losses, and reduced efficiency.

- Addressing this issue promptly helps prevent equipment damage and ensures reliable operation.

- Challenges in Detection:

- Detecting negative sequence currents is challenging without specialized equipment.

- Power Quality Monitors are essential for accurate measurements. These devices analyze voltage and current waveforms to identify imbalances.

- Other protective devices, such as Negative Sequence Current Protection, Differential Protection, or Voltage-Based Protection Relays, can be installed permanently.

- However, on medium voltage networks, the installation of such protective devices may be doubtful due to cost considerations or other factors.

In summary, while negative phase sequencing may go unnoticed by operators, investing in specialized equipment and protective relays is crucial for maintaining a healthy electrical system.

Actual Incident

Recently, I encountered another incident related to power quality. After analyzing the results from my Power Quality Monitor over the course of a week, I observed significant discrepancies in the current across the three phases. Under low load conditions, the currents seemed balanced, but as the load increased, one phase experienced a substantial increase in current, along with a corresponding rise in neutral current. This discrepancy concerned me, prompting further investigation. Upon closer examination, I discovered that the voltage on one of the phases had dropped to nearly negligible levels.

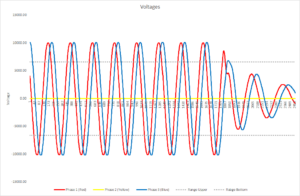

The image below illustrates how the voltages of Phases 1 and 3 surged during a swell incident, while Phase 2 (indicated in yellow) became almost negligible.

During a recent incident lasting 244 milliseconds, the voltages on Phase 1 and Phase 3 of what was supposed to be a 6.6 kV feeder exceeded 10 kV. Meanwhile, Phase 3 nearly reached 0 V. This substantial increase — over 51% above the rated voltage of the network — raises concerns and warrants further investigation to identify the cause of this voltage discrepancy

Follow-Up Investigations

Whether an investigation will be carried out and when is unpredictable.

This work was done for a consultant to determine whether additional load can be added without any upgrading of the network. It was done at a medium-voltage municipal substation with the knowledge and consent of the municipal engineering department. As a courtesy, the results were sent to the municipal engineering department by the consultant, and we must now wait for their reaction.

Agulhas Consulting Services

Kindly click on this page to learn more about Load Profiling specialist service we are offering.

Newsletter

Join the mailing list and receive our latest newsletters by simply filling in your email address below and then click Subscribe.